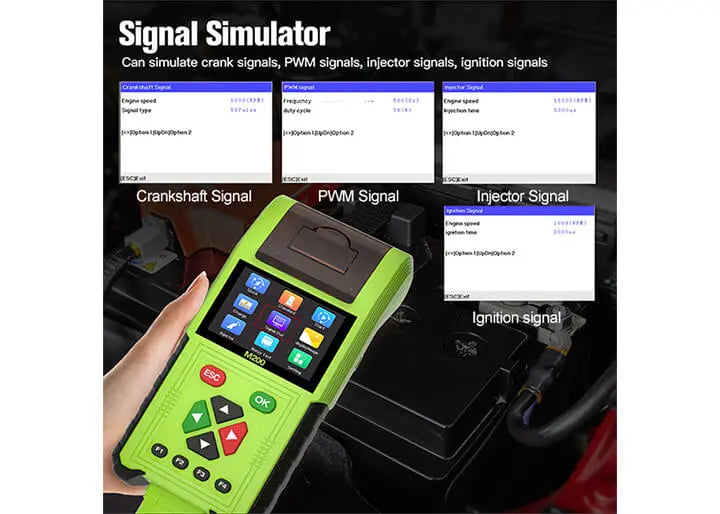

Crankshaft Signal

The JDiag M200's crankshaft signal simulation feature enables generate simulated signals that mimic the output of a vehicle's crankshaft position sensor. It can be applied in diagnosing and troubleshooting issues related to the engine's ignition and fuel injection systems.

Crankshaft Position Testing: Mechanics can simulate the crankshaft position sensor signals to verify if the sensor is functioning properly and providing accurate readings to the engine control unit (ECU). It can diagnose issues related to engine misfires, starting problems, and rough idling.

Ignition System Analysis: By simulating crankshaft signals, mechanics can assess the ignition system's response and ensure that the spark plugs are firing at the correct timing and sequence. It can help identify ignition-related problems such as misfires, weak sparks, or timing-related issues.

Fuel Injection System Evaluation: The crankshaft signal simulation allows mechanics to analyze the fuel injection system's performance by measuring the synchronization between injector pulses and the crankshaft position. Including fuel delivery issues, such as clogged injectors, faulty injectors, or incorrect fuel timing.

PWM Signal

Usually, PWM signals are applied in electronic control modules to control components such as solenoids, motors, valves, and actuators. The PWM signal simulator can assist in diagnosing and troubleshooting these systems.

Here's what the PWM signal simulator function of the JDiag M200 motorcycle obd 2 scanner can do:

Solenoid and Valve Testing: Mechanics can simulate PWM signals to test the operation and response of solenoids and valves. This helps diagnose issues related to transmission solenoids, variable valve timing (VVT) solenoids, EGR valves, throttle bodies, and other components that rely on PWM signals for precise control.

Actuator Evaluation: By generating PWM signals, mechanics can assess the performance of actuators like motors and servos. This allows them to verify if the actuator is functioning correctly and responding appropriately to the PWM input.

Sensor Simulation: The PWM signal simulator function can also be used to simulate PWM signals when testing sensors that respond to such signals. It allows mechanics to assess the sensor's accuracy, responsiveness, and overall functionality. This is beneficial in diagnosing faults in sensors like oxygen sensors (O2 sensors), ABS wheel speed sensors, and throttle position sensors (TPS).

Circuit and Wiring Checks: Mechanics can utilize the PWM signal simulator to verify the integrity of circuits and wiring related to PWM-controlled components. By generating simulated signals, they can trace wiring faults, identify open circuits, or detect short circuits that may affect the proper functioning of PWM-controlled systems.

Diagnosis and Troubleshooting: The PWM signal simulator function assists mechanics in diagnosing and troubleshooting complex automotive systems more effectively. By replicating PWM signals, they can isolate and determine whether the issue lies with the control module, the component being controlled, or the associated wiring.

Injector Signal

The injector signal function of the JDiag M200 motorcycle obd 2 scanner can monitor the signals being sent to the fuel injectors of a motorcycle engine. It can diagnose issues related to fuel injection, such as injector activation and timing.

When you use the injector signal function, the diagnostic tool connects to the motorcycle's ECU (Engine Control Unit) and captures the signals sent to the injectors.

By analyzing the injector signals, you can confirm if there are any abnormalities, such as misfires, inconsistent or weak injector pulses, or problems with the timing of the signals. This information can help you identify fuel injection issues and guide you in troubleshooting and resolving fuel system problems in the motorcycle.

Ignition Signal

The ignition signal simulation feature of the JDiag M200 motorcycle diagnostic tool is used for testing and troubleshooting the ignition system without having to actually start the engine.

With this feature, the machinist can simulate different types of ignition signals that would be generated by the motorcycle's ECU (Engine Control Unit) during normal operation. This includes simulating signals for specific ignition timing, RPM (Revolutions Per Minute), and other parameters related to the ignition system.

By simulating ignition signals, the machinist can confirm if the ignition system components, such as the ignition coil, spark plugs, and ignition control module, are functioning normally. The machinist can also test the response of the ignition system to different signal inputs and check for any abnormalities or faults.

Purchase Links:https://jdiagstore.com/products/jdiag-m300-motorcycle-obd-2-scanner-battery-tester

If you have any questions, please email us: service@jdiagshop.ntesmail.com